Öveçoğlu, M. Lutfi

Loading...

Profile URL

Name Variants

Öveçoğlu, M.L.

Öveçoğlu, Mustafa Lutfi

Ovecoglu, Mustafa Lutfi

Öveçoğlu, M. Lutfi

Lütfi Öveçoğlu, M.

Ovecoglu, Lutfi

Oveçoğlu, M. Lutfi

Öveçoğlu, Mustafa Lutfi

Ovecoglu, Mustafa Lutfi

Öveçoğlu, M. Lutfi

Lütfi Öveçoğlu, M.

Ovecoglu, Lutfi

Oveçoğlu, M. Lutfi

Job Title

Email Address

ovecoglum@mef.edu.tr

Main Affiliation

02.03. Department of Mechanical Engineering

Status

Current Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

2

ZERO HUNGER

0

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

1

NO POVERTY

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

1

Research Products

10

REDUCED INEQUALITIES

0

Research Products

3

GOOD HEALTH AND WELL-BEING

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

0

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

0

Research Products

5

GENDER EQUALITY

0

Research Products

14

LIFE BELOW WATER

0

Research Products

13

CLIMATE ACTION

0

Research Products

15

LIFE ON LAND

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

4

QUALITY EDUCATION

0

Research Products

Documents

232

Citations

3212

h-index

29

Documents

227

Citations

3106

Scholarly Output

12

Articles

12

Views / Downloads

2818/1544

Supervised MSc Theses

0

Supervised PhD Theses

0

WoS Citation Count

38

Scopus Citation Count

42

WoS h-index

3

Scopus h-index

3

Patents

0

Projects

0

WoS Citations per Publication

3.17

Scopus Citations per Publication

3.50

Open Access Source

1

Supervised Theses

0

| Journal | Count |

|---|---|

| Diamond and Related Materials | 2 |

| Advanced Engineering Materials | 2 |

| FlatChem | 1 |

| Intermetallics | 1 |

| International Journal of Refractory Metals and Hard Materials | 1 |

Current Page: 1 / 2

Scopus Quartile Distribution

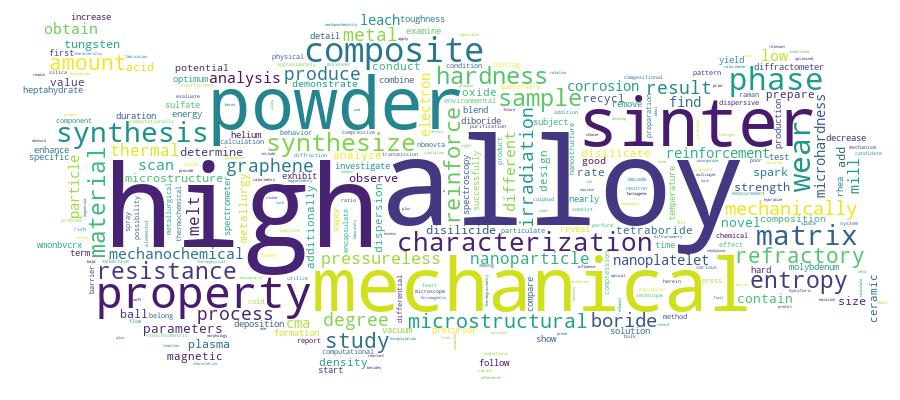

Competency Cloud

12 results

Scholarly Output Search Results

Now showing 1 - 10 of 12

Article Citation - WoS: 1Mechanochemical Synthesis and Characterization of Nanostructured Erb4 and Ndb4 Rare-Earth Tetraborides(John Wiley and Sons Inc, 2024) Boztemur, B.; Kaya, F.; Derin, B.; Öveçoğlu, M.L.; Li, J.; Ağaoğulları, D.Rare-earth borides have become very popular in recent decades with high mechanical strength, melting point, good corrosion, wear, and magnetic behavior. However, the production of these borides is very challenging and unique. The production of ErB4 and NdB4 nanopowders via mechanochemical synthesis (MCS) is reported in this study first time in the literature. Er2O3 or Nd2O3, B2O3, and Mg initial powders are mechanically alloyed for different milling times to optimize the process. Rare-earth borides with MgO phases are synthesized, then MgO is removed with HCl acid. The nanostructured rare-earth tetraboride powders are analyzed using X-ray diffraction (XRD). Based on the XRD, ErB4 powders are produced successfully at the end of the 5 h milling. However, the NdB4 phase does not occur as the stoichiometric ratio, so the B2O3 amount is decreased to nearly 35 wt%. When the amount of B2O3 is decreased to 20 wt%, NdB4 and NdB6 phases are 50:50 according to the Rietveld analysis. However, a homogenous NdB4 phase is obtained with 30 wt% loss of B2O3. The average particle sizes of ErB4 and NdB4 powders are nearly 100.4 and 85.6 nm, respectively. The rare-earth tetraborides exhibit antiferromagnetic-to-paramagnetic-like phase transitions at 18 and 8.53 K, respectively. © 2024 The Author(s). Advanced Engineering Materials published by Wiley-VCH GmbH.Article Citation - WoS: 3Citation - Scopus: 3Powder metallurgy processing of seven/eight component multi-phase (HfTiZr-Mn/Mo/W/Cr/Ta)B2 high entropy diboride ceramics(Elsevier, 2024) Suzer, Ilayda; Akbari, Amir; Ates, Semih; Bayrak, Kuebra Gurcan; Mertdinc-Ulkuseven, Siddika; Arisoy, C. Fahir; Agaogullari, Duygu; Öveçoğlu, M. LutfiThis study aims to show the possibility of synthesizing seven- and eight-component high entropy diboride (HEB) ceramics using high energy ball milling-assisted spark plasma sintering (SPS). Metal boride powders, synthesized in laboratory conditions from metal oxide-boron oxide-magnesium powder blends, were combined equimolarly as seven and eight components containing systems. Afterwards, hybridized powders were mechanically alloyed (MA) for 6 h and subjected to spark plasma sintering (SPS) at 2000 degrees C and under 30 MPa. Detailed phase analysis and physical, microstructural, and mechanical characterization of the samples were performed. in the sintered products, the main phase belongs to the HEB, and also low amounts of Hf/Zr oxides and secondary phases (W or Ti-rich) occurred. The highest hardness was observed at the (HfTiZrMoWCrTa)B-2 with 25 GPa, and the lowest hardness was seen at the (HfTiZrMnCrMoWTa)B2 with 17 GPa. Also, the highest wear resistance was calculated for the (HfTiZrMnCrMoTa)B-2 as 6.05 x 10(-7) mm(3)/Nm. Additionally, (HfTiZrMnMoWTa)B-2 and (HfTiZrMnMoCrTa)B-2 have the highest and lowest Archimedes' densities, with 7.94 g/cm(3) and 6.91 g/cm(3), respectively.Article Citation - WoS: 1Citation - Scopus: 1Powder Metallurgical Processing of Al–5 Wt% Cu Matrix Composites Reinforced With Mosi2 and Wsi2 Particulates(John Wiley and Sons Inc, 2025) Mertdinç-Ülküseven, S.; Ovalı-Döndaş, D.; Süzer, İ.; Altıntaş, M.; Can Karaca, M.; Özal, B.; Öveçoğlu, Mustafa LütfiHerein, investigations on the microstructural, physical, and mechanical properties of molybdenum disilicide (MoSi2)- and tungsten disilicide (WSi2)-reinforced aluminum (Al)–copper (Cu) matrix composites are reported. Powder metallurgy methods such as mechanochemical synthesis (MCS), mechanical alloying (MA), cold pressing, and pressureless sintering are combined to produce composites. First of all, MoSi2 and WSi2 nanoparticles are synthesized by MCS and selective acid leaching, yielding reinforcement materials for Al–Cu matrix. Powder blends consisting of 95 wt% Al and 5 wt% Cu are mixed with metal disilicides at different weight percentages (1, 2, and 5 wt%). MA for 4 h is conducted on these overall blends using a high-energy ball mill. Microstructural and thermal properties of the as-blended and mechanically alloyed powders are determined, and then they are compacted under 450 MPa and sintered at 550 °C for 2 h. Mechanical characterization of the composites reveals an increase in hardness and wear resistance with an increasing amount of reinforcement content. Among bulk samples, 5 wt% WSi2-reinforced composites have the highest microhardness (165 ± 15 HV) and lowest wear rate (1.69 × 106 μm3 Nm−1) values. However, under the compression forces, the highest toughness and strength are obtained from 2 wt%-reinforced composites. © 2024 Wiley-VCH GmbH.Article Nbmovta Refractory High-Entropy Alloy Incorporated Wni Matrix Composite as a Future Plasma-Facing Material: Evaluation of Mechanical Properties and Helium Ion Irradiation Behavior(Elsevier Sci Ltd, 2025) Boztemur, Burcak; Filiz, Kaan; Karaguney, Zahide; Gokaydin, Eyupcan; Bozkurt, Yasin; Ozbasmaci, Ceren; Ovecoglu, M. LutfiRefractory high-entropy alloys (RHEAs) have gained attention in the last decades with their high mechanical strength, self-healing mechanism, and high irradiation resistance. These materials are evaluated to have a high potential as plasma-facing materials for fusion reactors. In this study, helium ion irradiation and mechanical behaviors of the RHEA-reinforced WNi matrix composites were investigated based on this perspective. Equimolar molybdenum, niobium, tantalum and vanadium powders were mechanically alloyed for 6 h to produce NbMoVTa RHEA with a single BCC phase. Then, different amounts (10, 20, 30, and 40 wt%) of RHEA were added into the W1Ni (containing 99 wt% W and 1 wt% Ni) matrix by planetary ball milling for 72 h. Consolidation was conducted by spark plasma sintering technique (1410 degrees C, 1 min). X-ray diffraction, scanning electron microscopy coupled with energy dispersion spectroscopy, and Archimedes' density analyses were performed on the composites. Moreover, wear and hardness properties of the composites were examined, and the lowest specific wear rate (0.59 mm3/N.m x 10- 5) and the highest hardness value (10.10 GPa) were found for the W1Ni-40RHEA composite. Helium irradiation was exposed to the composites to observe their irradiation resistance. It was observed that the lowest increment and the least deformation were obtained with the SPS'ed W1Ni-40RHEA composite. With the analysis of He+ irradiation, it was determined that the effect of radiation on mechanical properties is irrelevant. Also, it was observed that the addition of RHEA into the W matrix can create a high potential for using plasma-facing material. Moreover, it decreased the problems of tungsten against He+ irradiation.Article Powder Metallurgical Synthesis, Thermochemical Calculations and Characterization Studies of HfB2 Powders(Springer India, 2025) Akbari, Amir; Suzer-Cicek, Ilayda; Mertdinc-Ulkuseven, Siddika; Gokce, Hasan; Ovecoglu, M. Lutfi; Agaogullari, DuyguThis study reports on the thermochemical calculations, mechanochemical synthesis, purification process, and characterization studies of the HfB2 powders by using native sources. Firstly, HfO2, native B2O3, and Mg starting powders were prepared with a multi-axial vibratory ball mill (NanoMultimix) in stoichiometric and excess amounts. The milling process was optimized by varying the time (2, 4, 6, 8, 10, 12 h). Then, unwanted by-products (HfO2, MgO) were removed by leaching with 4 and 6 M HCl. Phase and Rietveld analysis, microstructure investigations with scanning electron microscopy/energy dispersion spectroscopy and transmission electron microscopy, and particle size measurement were conducted. The purest HfB2 was obtained in the powders milled for 8 h in stoichiometric ratios and leached with 6 M HCl. The resulting optimum powder has an average particle size of 135 nm. Oxidation kinetics (500, 600, 700, 800, and 900 degrees C) were also investigated. As the temperature increased, the amount of oxidation increased based on the TG result. As a result of the characterization studies, the synthesis of single-phase, high-purity HfB2 was achieved using domestic resources.Article Citation - WoS: 9Citation - Scopus: 12Microstructural, Thermal Characterization and Cmas Corrosion Resistance of Novel Quaternary (y0,25er0,25tm0,25yb0,25)2si2o7 High Entropy Disilicate Material(Elsevier Sci Ltd, 2024) Çınar, Muharrem Mert; Akyürek, Öykü; Yüksek, Ahmet Numan; Ağaoğulları, Duygu; Acem, Ümran; Öveçoğlu, Mustafa Lutfi; Kavak, Sina; Gençer, RabiaA novel (Y0,25Er0,25Tm0,25Yb0,25)2Si2O7 high entropy disilicate quaternary composition was synthesized from commercial oxide powders using ball milling and sintering processes as a candidate material for environmental barrier coatings (EBC). As-synthesized high entropy disilicate powders were sintered at different durations (12, 18, and 24 h) at 1600 degrees C in a muffle furnace before characterization. The XRD and SEM analyses revealed the single-phase monoclinic structure (beta-type) with homogeneous elemental distribution for the sintered samples. The (Y0,25Er0,25Tm0,25Yb0,25)2Si2O7 samples exhibited low thermal diffusivity coefficient, low thermal conductivity, a close coefficient of thermal expansion (CTE) to SiC and a high temperature stability. The (Y0,25Er0,25Tm0,25Yb0,25)2Si2O7 samples were subjected to CMAS corrosion tests at 1300 degrees C with different durations (2, 12, and 24 h) to evaluate CMAS corrosion resistance. Additionally, Yb2Si2O7 samples were prepared and subjected to molten CMAS in the same way for comparison. Based on the results, the CMAS corrosion resistance was improved with (Y0,25Er0,25Tm0,25Yb0,25)2Si2O7 composition.Article Citation - WoS: 8Citation - Scopus: 9Graphene Nanoplatelet Reinforced Al-Based Composites Prepared From Recycled Powders Via Mechanical Alloying and Pressureless Sintering(Elsevier Science Sa, 2024) Süzer, İlayda; Hayırcı, Sena Burcu; Boyacı, Ege; Deniz, Ayşe; Mertdinç Ülküseven, Sıddıka; Öveçoğlu, Mustafa Lutfi; Ağaoğulları, DuyguThis study reports on the powder metallurgy preparation and characterization of aluminum-graphene nanoplatelet (Al-GNP) composites synthesized using recycled Al powders. Recycled Al and GNP powders (0.1-1 wt%) were mechanically alloyed (MA'd) for 4 h, followed by cold pressing (at 450 MPa) and pressureless sintering at 590 degrees C for 2 h. Starting powders were analyzed using an optical emission spectrometer (OES) and a Raman spectrometer. Also, MA'd powders and sintered samples were characterized using an X-ray diffractometer (XRD), a scanning electron microscope/energy dispersive spectrometer (SEM/EDS), and a differential scanning calorimeter (DSC). Particle size analyses, pycnometer, and Archimedes' densities, Vickers microhardness, dry-sliding wear, and compression tests were also conducted. The Al4C3 formation was observed in the XRD patterns of sintered compositions. The highest and lowest relative densities were measured for the 1 wt% and 0.1 wt% GNP reinforced samples as 97 % and 92 %, respectively. The highest hardness value was obtained as approximately 1.31 GPa for 1 wt% GNP reinforced. With the addition of reinforcement GNP, the wear rate developed to approximately 0.00225 mm3/Nm. The compressive strength increased from nearly 70 MPa to 162 MPa.Article Citation - WoS: 2Citation - Scopus: 2Effect of Reinforcement Amount on the Microstructural and Mechanical Properties of Mechanically Alloyed Graphene Nanoplatelet Reinforced Al-3.5 Wt% Cu Composites(Elsevier Science, 2025) Mertdinç-Ülküseven, Sıddıka; Süzer, İlayda; Ürper, Ahmet Kasım; Çelik, Alper İbrahim; Bacı, Doruk Tuncer; Gürarslan, Kerem Alper; Ağaoğulları, Duygu; Öveçoğlu, M. LütfiIn this study, various amounts (0.25, 0.5, 0.75, 1, and 2 wt%.) of graphene nanoplatelets (GNPs) reinforced Al-3.5 wt% Cu metal matrix composites were produced using powder metallurgy processes consisted mechanical alloying and pressureless sintering. To compare the properties of the sintered composites, as-blended and 4 h mechanically alloyed powders were sintered to yield Al-3.5 wt% Cu matrix alloys. The microstructural, thermal and mechanical properties were examined using relevant characterization techniques. The formation of Al2Cu phase was detected at all XRD patterns of the sintered samples other than matrix and reinforcement phases. Mechanically alloyed powders exhibit the equiaxed particle morphology compared to the as-blended ones, their mechanical properties were found better than as-blended and sintered samples. Additionally, mechanical alloying led to the dispersion of GNP reinforcements into the AlCu matrix. The highest hardness value (around 153 HV) was obtained for 2 wt% GNP reinforced composite. The highest wear resistance was recorded for 1 wt% GNP reinforced composite with 2.07 +/- 0.2 mm(3)/N.mx10(-3) wear rate. Additionally, composites' compressive strength improved with adding 1 wt% GNP (similar to 68.5 MPa). The good dispersion of the optimum amount of GNP's via mechanical alloying provide to obtain preferable mechanical properties.Article Room-Temperature Synthesis of Refractory Borides: a Case Study on Mechanochemistry and Characterization of Mo-Borides and W-Borides(Elsevier Sci Ltd, 2025) Süzer, İlayda; Akbari, Amir; Kaya, Faruk; Mertdinç Ülküseven, Sıddıka; Derin, Bora; Öveçoğlu, M. Lütfi; Ağaoğulları, DuyguMo-boride and W-boride powders were produced from native boron oxide, magnesium, and related metal oxide starting materials by mechanochemical synthesis (MCS) followed by an purification treatment. The reaction formation mechanisms and the products were predicted with the FactSageTM thermochemical simulation program. Different conditions were tested to determine the optimum synthesis parameters. MCS was conducted at stoichiometric ratios and different milling durations, using excess reactant amounts over the determined optimum time. After MCS, unwanted phases were removed by HCl acid leaching. Detailed phase analyses of the final powders were obtained by X-ray diffractometer (XRD), whereas detailed microstructure characterization was conducted by scanning electron microscope/energy dispersion spectrometer (SEM/EDS), transmission electron microscope (TEM) and particle size analyzer. Among the utilized parameters, the ideal composition chosen for Mo boride synthesis was 6 h milled and leached MoO3-100 wt% B2O3-50 wt% Mg (1.41 mu m), including alpha-MoB, beta-MoB, MoB2, Mo2B, Mo2B5, and Mo phases. For the synthesis of W boride, the proper composition was found as WO3-100 wt% B2O3-50 wt% Mg (0.37 mu m) containing W2B5, WB, beta-WB, WB4, W2B, and W phases after milling for 20 h and leaching. Besides, as a result of the oxidation resistance measurements at 700 and 800 degrees C, phases belonging to MoO2 and WO2 were found along with boride phases.Article Citation - WoS: 1Citation - Scopus: 1A Novel Plasma-Facing Ndb6 Particulate Reinforced W1ni Matrix Composite: Powder Metallurgical Fabrication, Microstructural and Mechanical Characterization(Elsevier Sci Ltd, 2024) Boztemur, Burçak; Öveçoğlu, Mustafa Lutfi; Luo, Laima; Ağaoğulları, Duygu; Xu, Yue; Alkraidi, AmmarTungsten (W) is one of best candidate metal for plasma-facing materials (PFM), especially due to its high melting temperature and neutron absorption capability. However, converting W into bulk PFM is hard because of its high melting point. This problem can be solved by adding metallic sintering aids with low melting points. In this study, W matrix with 1 wt% Ni aid was reinforced by adding NdB6 particles (1, 5, and 10 wt%). It can be introduced as a novel potential PFM, thanks to its low volatility and high neutron absorbability. The ceramic and composite powders produced via mechanochemical synthesis and mechanical alloying were examined in terms of composition, particle size, crystallite size, and lattice strain. Samples sintered via pressureless sintering (PS) and spark plasma sintering (SPS) were microstructurally analyzed by using an X-ray diffractometer (XRD), a scanning electron microscope (SEM) attached with an energy dispersive spectroscope (EDS), and mechanically analyzed in terms of microhardness and wear behavior. Based on the results, W2B and WB phases emerged in the SPS'ed W1Ni-5NdB6 and PS'ed./SPS'ed W1Ni-10NdB6 composites. SPS'ed W1Ni-10NdB6 composite had the highest hardness value and the lowest specific wear rate. The SPS'ed W1Ni-5NdB6 composite showed fewer surface damages and higher irradiation resistance as compared with other samples after exposure of He+ irradiation.